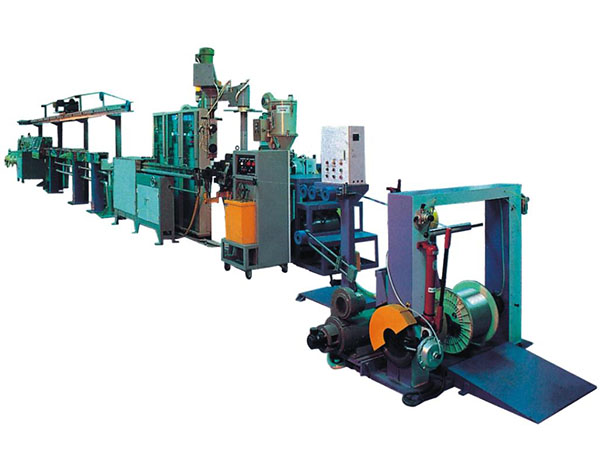

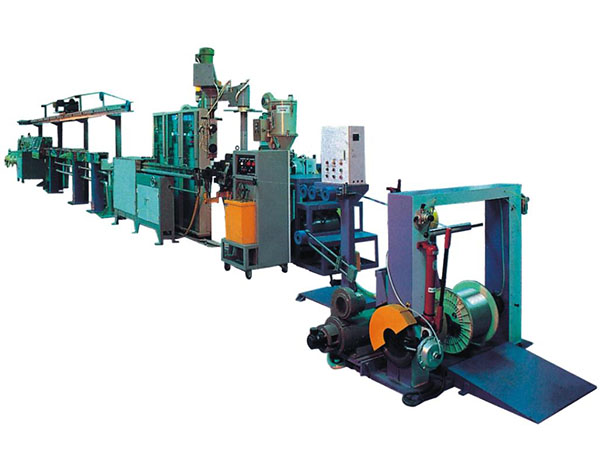

Suitable for extrusion of various low-smoke halogen-free cables and cross-linked polyethylene (XLPE) cables.

Screw barrel: Adopting the latest structural design of Japan, and according to different extrusion process requirements, special reinforcement structure is applied to apply various types of low-smoke and halogen-free extrusion.

Handpiece: Low smoke zero halogen or XLPE special handpiece.

Heating and cooling system: With the special design of the screw barrel, this machine is equipped with a unique heating and cooling system to meet the requirements of precision extrusion of different rubber compounds.

Extrusion machine: This machine can be equipped with suitable auxiliary machines (30, 35, 40, etc.) according to different process requirements. After replacing the machine head and screw, nylon sheathed wire can be produced. It can meet different process requirements such as single note strip, double note strip and double layer coextrusion.

Quality Control: Equipped with an outer diameter detection and anti-dish device to control the outer diameter and concentricity of the product to avoid the cable diameter and insulation thickness error, resulting in increased production costs.

Electronic control: Inverter, PLC touch screen control.

APP

APP  Applets

Applets  No public

No public